Replacement Bed Foot

Replacement bed foot designed after the original component failed. The part was reverse engineered to match fit and interface geometry, then evaluated under expected loading to ensure adequate strength. Final part was fabricated and installed with no issues in service.

The Problem/Requirement

- Original bed foot failed

- Queen bed with metal frame

Designed load per foot: 300 lbs

Worst case scenario of large person sitting on corner of bed

- Goal: Reverse engineer part to match fit and function of original. This component shares the weight of the entire bed and its occupants, so it needs to be able to withstand a moderate amount of force and potential impacts.

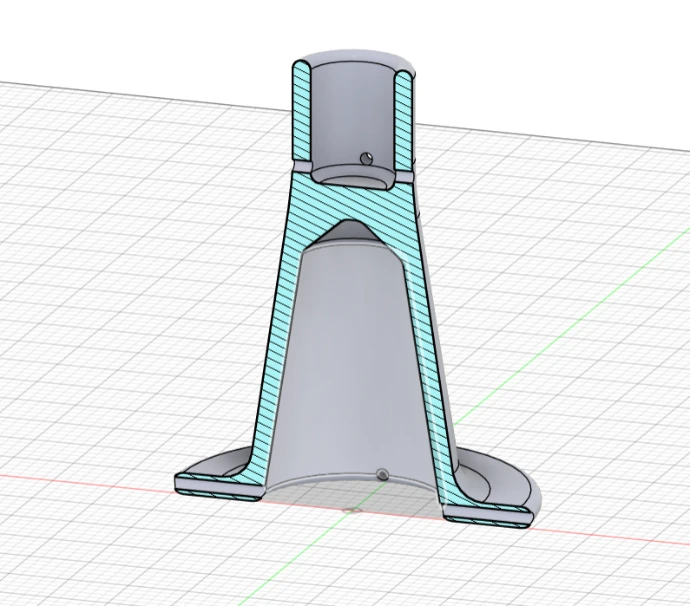

Design Approach

For the process, I chose to use SLA resin printing due to its isotropic mechanical properties.

For the material, I chose to use Formlabs Tough 2000 resin, which offers good strength and impact resistance.

Reverse-engineering the part required precision measuring equipment to ensure a tight fit.

The design process also included adding vent holes to prevent cupping. This part will be printed directly on the build plate to reduce material cost, and the internal features create a "cup" that would cause suction forces that could cause printing issues.

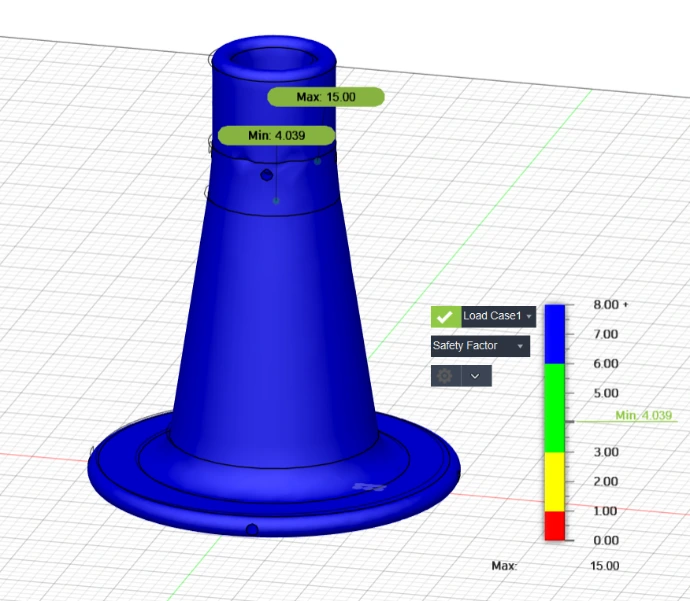

Validation/Evaluation

The part was then load tested to ensure it can handle the designed load of 300 lbs.

The goal was to have a safety factor of 3 or greater to ensure the part would be able to handle someone abruptly sitting on the bed.

The load simulation was well beyond the required safety factor.

Production

- After all validation efforts were completed, the part was printed out of the chosen Tough 2000 resin.

- Printing the part was simple because it was designed specifically with printing in mind. Due to the efficient design, post-processing was simple.

- The parts were then washed and cured per Formlabs's specifications to ensure designed mechanical properties.

Results/Conclusion

After final production, the part was installed and tested. It met the requirements of the project well and matched the appearance of the original injection-molded feet. This part been in-use for months with no issues.

Have a similar problem?

Contact us today for a free quote or to discuss your ideas.