Case Studies

Selected examples of custom design, reverse engineering, and functional prototyping.

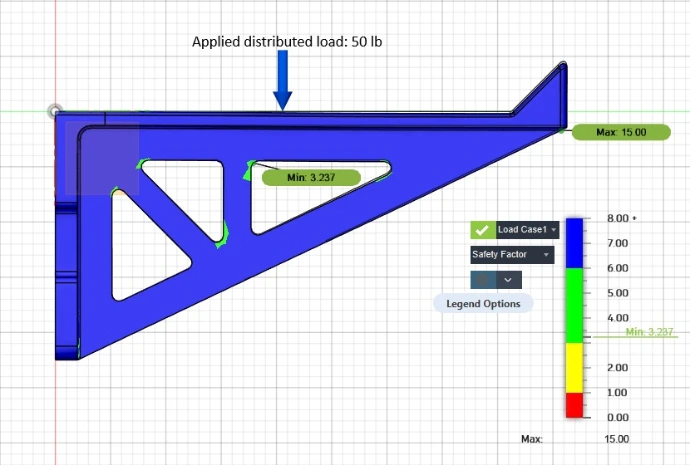

Lightweight Ladder Support Bracket - Load-Validated Design

Lightweight ladder support bracket designed to meet a defined load requirement while minimizing material. The part was modeled in CAD, evaluated under a distributed load in simulation, and refined to improve strength-to-weight performance. Final design was fabricated and validated in real-world use.

View Case Study

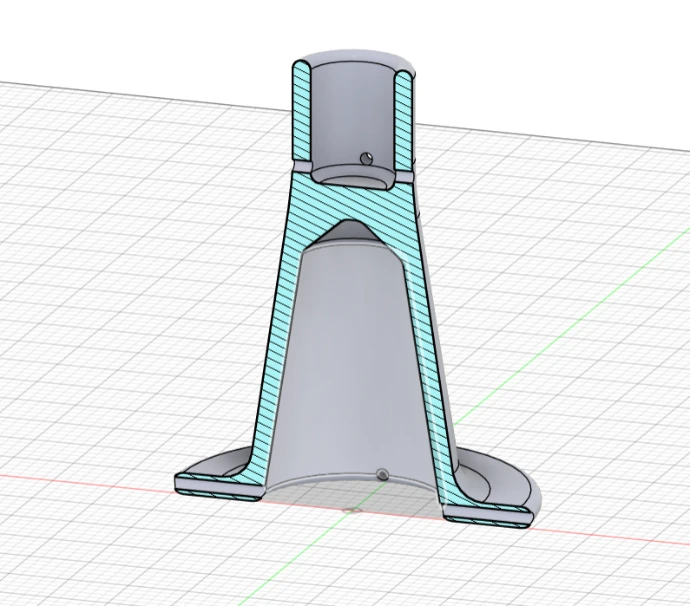

Replacement Bed Foot - Reverse Engineered & Load-Validated

Replacement bed foot designed after the original component failed. The part was reverse engineered to match fit and interface geometry, then evaluated under expected loading to ensure adequate strength. Final part was fabricated and installed with no issues in service.

View Case Study

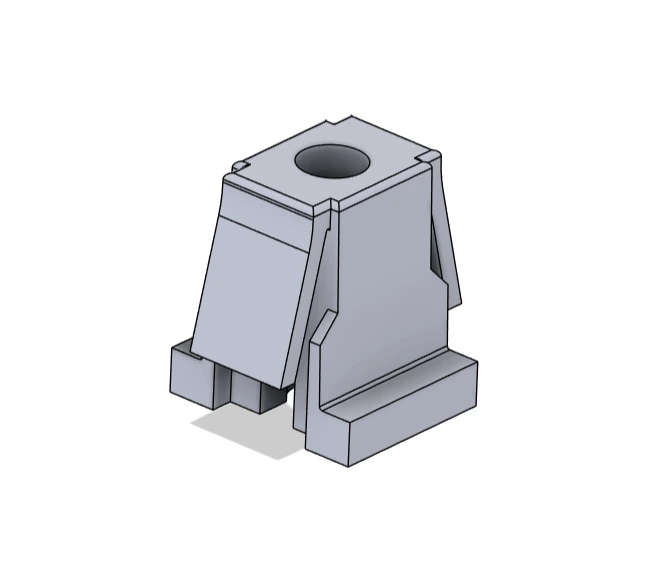

Headlight Adjuster - Reverse Engineered & Tested

Custom replacement headlight adjustment component created after the original part failed. The geometry was reverse engineered to restore proper adjustment and fit within the existing assembly. The part has been in service for months with no functional issues.

View Case Study

Headlamp - Reverse Engineered & Tested

Reverse-engineered headlamp enclosure recreated to capture intricate geometry and fine functional details. The original part was measured and modeled in CAD, critical interfaces were preserved, and the design was prepared for resin printing. The final part was printed in high-resolution resin and validated for fit, finish, and function.

View Case Study

Additional Projects

A collection of smaller projects that highlight my CAD, Reverse Engineering, and 3D Printing capabilities.

Vacuum Crevice Tool

Custom vacuum attachment designed to access tight crevices.

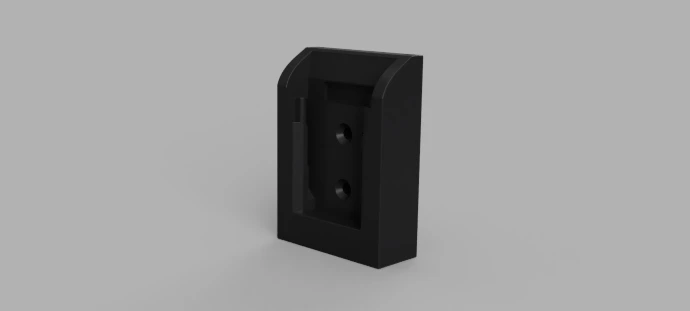

DeWalt Battery Wall Mount

Wall-mounted battery holder designed for secure storage and quick access.

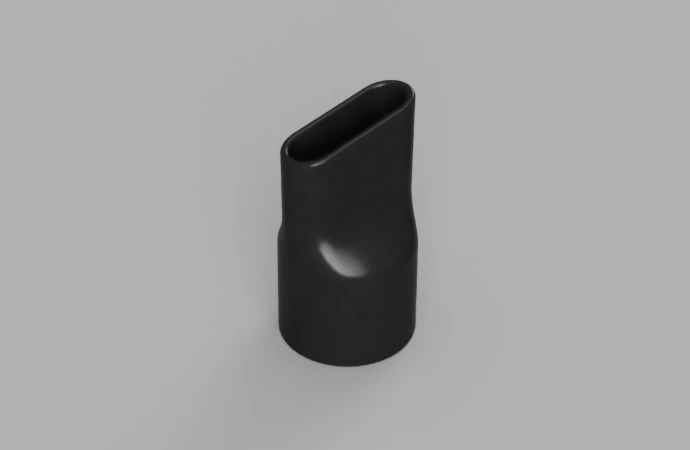

Vacuum Sander Attachment

Attachment designed to quickly attach vacuum hose to sander for dust collection.

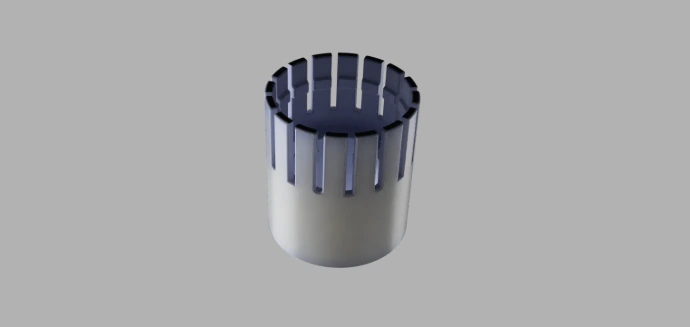

Oil Filter Socket

Oil filter socket designed and printed to replace an off-the-shelf tool that did not fit the application.

Cabinet Drawer Guide

Replacement guide designed and printed for worn dovetail drawer slide.

Light Globe

Replacement light globe reverse engineered and printed out of clear resin.

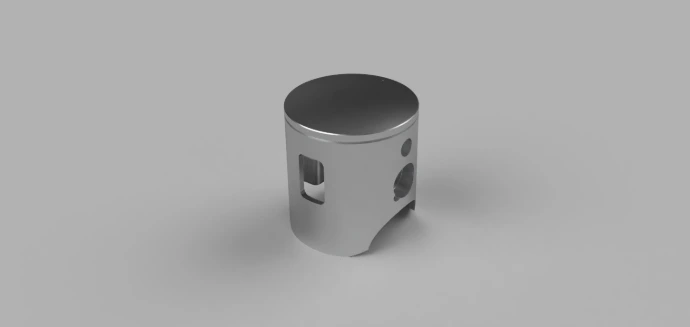

Dirt Bike Piston

Reverse engineered piston from an old dirt bike to create an accurate CAD model for analysis.

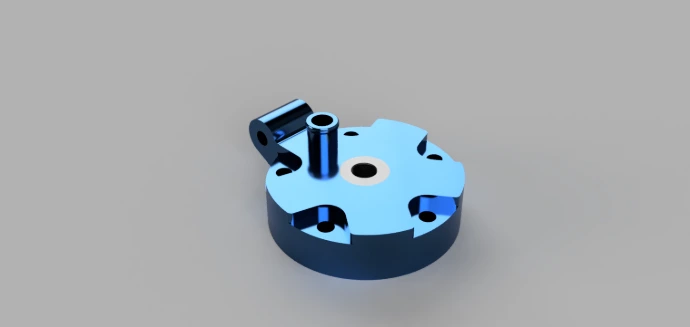

Machinable Dirt Bike Cylinder Head

Reverse engineered cylinder head from an old dirt bike and modified for machinability. Required splitting into two pieces to accommodate the coolant passages.

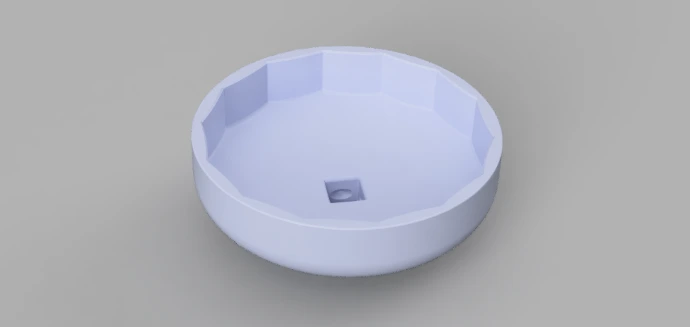

Shower Knob

Replacement shower knob designed and printed to achieve custom look not available off-the-shelf.

Have a similar problem?

Contact us today for a free quote or to discuss your ideas.