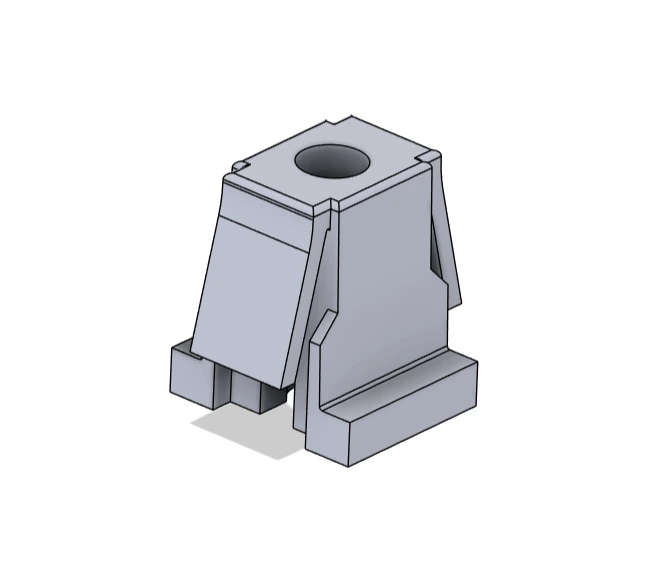

Headlight Adjuster

Custom replacement headlight adjustment component created after the original part failed. The geometry was reverse engineered to restore proper adjustment and fit within the existing assembly. The part has been in service for months with no functional issues.

The Problem/Requirement

- OEM part failed after many years of use.

- Unable to source replacement part from local or online retailers.

- Goal: Reverse engineer part to match fit and function of original.

Design Approach

For the process, I chose to use SLA resin printing due to its isotropic mechanical properties and lack of layer adhesion issues.

Unlike typical FDM 3D printing, SLA does not suffer from having separate layers. This allows parts to be bent, stressed, and loaded in all orientations without risk of inconsistent mechanical properties - perfect for a product that needs to bend repeatedly such as this one.

For the material, I chose to use Formlabs Tough 2000 resin, which offers good strength and durability.

Reverse-engineering the part required precision measuring equipment to ensure a tight fit.

Production

- After all design efforts were completed, the part was printed out of the chosen Tough 2000 resin.

Printing the part required a couple key considerations.

- The critical interface/fitment surface is the top of the part because it needs to fit through the mating hole on the car. To reduce post-processing on this region, the part was oriented to print with the opposite surface directly on the build plate.

- With the above orientation, the print also required supports for the bending tabs.

- The parts were then washed and cured per Formlabs's specifications to ensure designed mechanical properties.

- The final step of the process was tapping the center hole to mate properly with the existing fastener. The chosen Tough 2000 resin was easy to work with, and the threads came out well.

Results/Conclusion

After final production, the part was installed and tested. It met the requirements of the project and has been in-use for several months with no issues. I have since had to replace the remaining OEM headlight adjusters, and this custom solution has worked every time.

Have a similar problem?

Contact us today for a free quote or to discuss your ideas.