Lightweight Ladder Support Bracket

Lightweight ladder support bracket designed to meet a defined load requirement while minimizing material. The part was modeled in CAD, evaluated under a distributed load in simulation, and refined to improve strength-to-weight performance. Final design was fabricated and validated in real-world use.

The Problem/Requirement

- 24 ft Fiberglass Extension Ladder

- 50 lb total weight

- Goal: Design most lightweight support bracket that can withstand the load with a sufficient safety factor. The bracket should also be capable of withstanding mild impact if ladder is lightly dropped onto bracket.

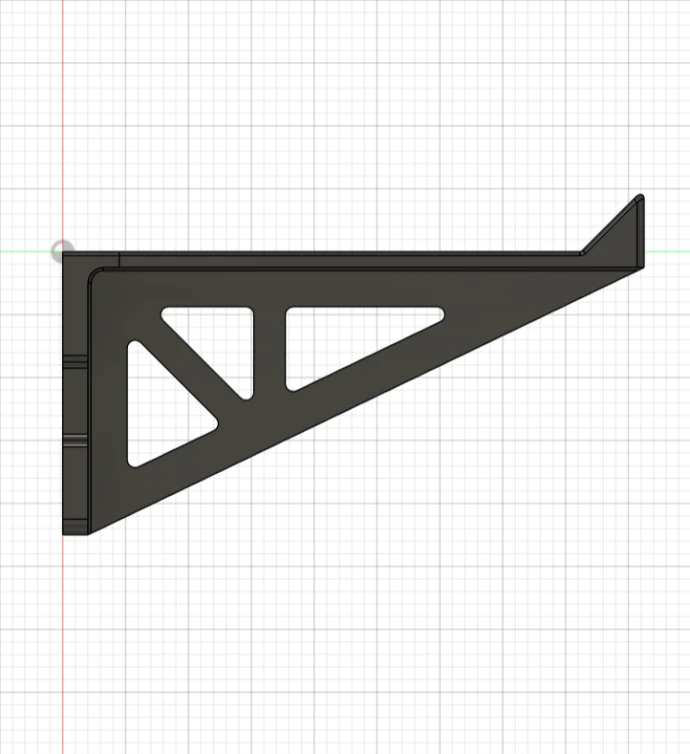

Initial Design

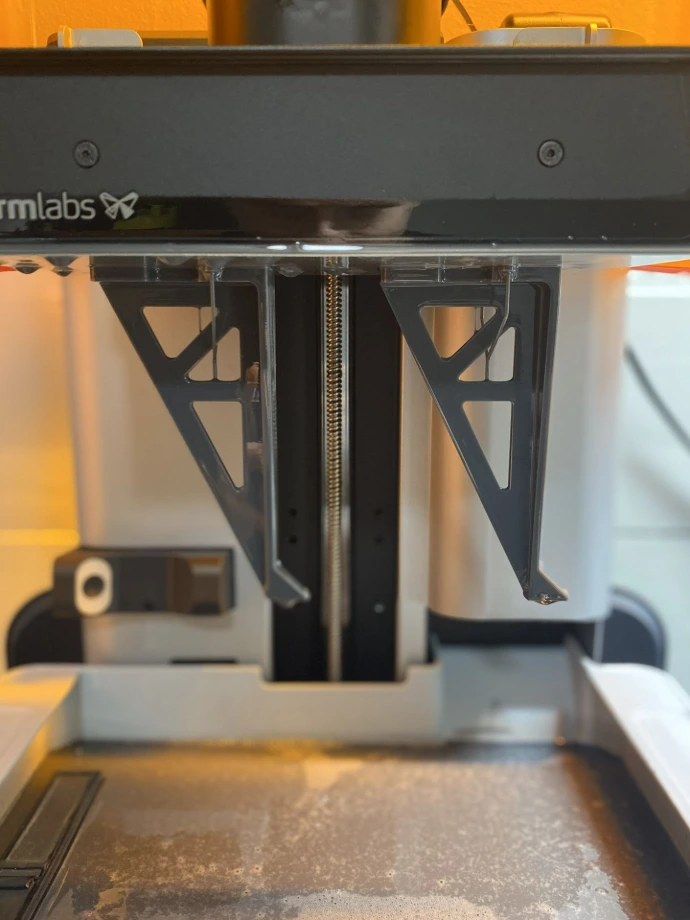

For the process, I chose to use SLA resin printing due to its isotropic mechanical properties.

For the material, I chose to use Formlabs Tough 2000 resin, which offers good stiffness and impact resistance.

Other key design criteria/choices

Fasteners: #9x3 in Deck Screws

.200 in major diameter

.350 in head diameter

82 deg countersink angle

Material thickness = .125 in

This design was load tested and verified to be well beyond the desired factor of safety, making it suitable for further weight reduction.

To verify the load simulation and general fit/function, a prototype was printed out of PLA Tough+. Upon installation, it was determined the part could be smaller too.

Revised Design

After the initial design was validated, the following improvements were made.

- The overall size was reduced by over 40%.

- The solid rib was replaced with a truss design, reducing the volume by ~15%

- Excess material between the mounting holes was removed. This had minimal impact on the overall performance of the part in the designed use-case, and reduced the volume by ~10%.

- A lip was added to the end of the bracket to prevent the ladder from sliding off.

Final Validation

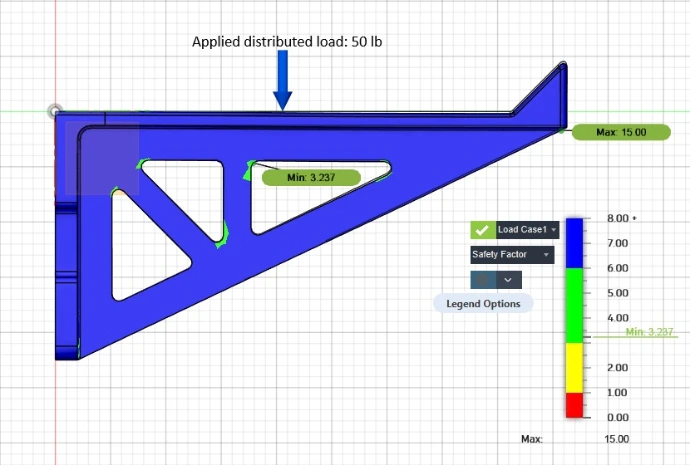

After the design was revised, it was validated with the following load case.

Applied distributed load: 50 lb

- Chosen to simulate one bracket supporting the entire weight of the ladder

- Constraints: Main load bearing on screw countersinks, secondary constraint from wall

- Results: Minimum safety factor of 3.237

- The final design was printed out of PLA Tough+ for a final prototype.

Production

- After all validation efforts were completed, the part was printed out of the chosen Tough 2000 resin.

- Printing the part was simple because it was designed specifically with printing in mind. Due to the efficient design, post-processing was simple.

- The parts were then washed and cured per Formlabs's specifications to ensure designed mechanical properties.

- The parts were then coated with a UV-resistant coating to prolong the lifespan.

Results/Conclusion

After final production, the parts were installed and tested. They meet the requirements of the project well and make ladder storage easier. The parts have been in-use with no issues since installation.

Have a similar problem?

Contact us today for a free quote or to discuss your ideas.